Introduction

China manufacturing has been the world’s largest in terms of its overall output. After all, they are earning their reputation as the “world’s factory” soon after being an addition to the World Trade Organization (WTO) in 2001.

With their commitment to opening up its economy, manufacturing in China comes with the appeal to cheap labour & low tariff access for Western markets. As China suppliers venture into the WTO, many foreign firms and investors rushed to capitalize in the world’s most populated country, kicking off the new millennium.

With the government’s shift towards this investment, manufacturing in China has become a world leader in the steel, car parts, chemicals, electronics, and robotic side of production.

Latest Numbers

China’s supplier PMI rose to 51.9 as of March 2021, showing that their manufacturing sector has maintained a strong recovery following the Chinese New Year holidays.

- China’s output index gained 2.0 points, reflecting growth in manufacturing production.

- By returning to the expansionary zone, China’s manufacturers have export orders that jumped by 2.4 pts, reflecting growth for external demand.

- While the index has risen to a four-year high, this suggests a pressure of heightened costs for manufacturing in China.

How Has Manufacturing in China Evolved?

It all started even before the coronavirus pandemic or the trade war between China and the US. Companies have been relocating production out of China before then. Relocation from those low-margin, labour-intensive industries began moving to Southeast Asian countries.

Countries like Thailand and Indonesia are growingly competitive since manufacturing in China began the rising cost of wages, land and taxes. Bangladesh has been another option for cheaper locations for industries under clothing and footwear production.

Factories in China have been assembling components that were made in other countries, which were the source of China’s export growth over the initial time before.

However, as China manufacturers have been working towards their locally-produced components with higher-value goods (like smartphone assembly for instance), many are starting to move towards cheaper countries like India and Vietnam.

How Is China Trying To Upgrade Its Manufacturing Industry?

A study from Beijing’s Renmin University of China in July 2019 highlighted that attaining the government’s goal of having newer industries account for 30% of GDP could take longer than 35 years.

The study also pointed out the excessive use of industrial subsidies, poor implementation of anti-pollution standards, and inability to help small & private firms handle short-term operational difficulties. All of which have stunted the necessary innovation process to upgrade China’s manufacturing base.

China’s Ministry of Industry and Information Technology has set out guidelines to promote upgrading the country’s vast manufacturing system in November 2019.

Video by SCMP. Millions of new blue-collar jobs are piling on the pressure for many workers in China

The plan focuses on the idea of strong innovation and great industry influence of shared manufacturing platforms. Having them built by 2022, they would be “key drivers for high-quality growth” by 2025.

While the ministry did not name specific platforms or any potential candidates, it clarified that this plan of shared production facilities would also include intellectual resources such as product design and development capabilities.

The guidelines said that China’s manufacturing-related services such as storage space and logistics could also be shared, hoping to boost resource allocation, improve efficiency, and cut idle capacity amongst large, medium-sized, and small businesses.

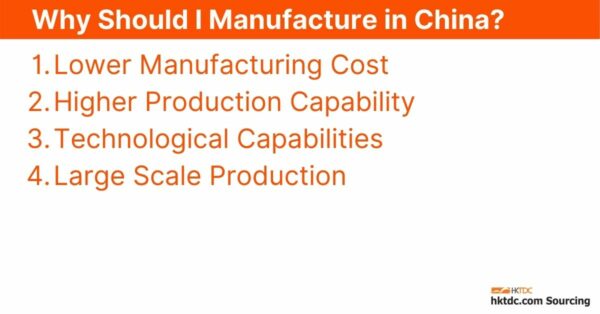

Why Should I Source from China?

Whether you are skeptical about manufacturing in China, the following will describe the reasons to settle for the Chinese state.

Lower Manufacturing Cost

Lower manufacturing costs are one of the most popular benefits of manufacturing in China. When compared to other domestic and overseas, manufacturing in China carries a great cost production difference by a large margin because of the experience accumulated over the years!

On the one hand, local manufacturing has higher training costs, while China’s manufacturing sector has lower training costs. On the other hand, while turnover rates are relatively higher for China’s manufacturers, the lower training costs would take care of this issue.

When sourcing your product over from China, you have the opportunities that come with low manufacturing prices – which is higher profits. China becomes a very suitable manufacturing environment due to the sustainability of their resources, along with the professionalism and politeness embedded within the Chinese values and customs.

Higher Production Capability

Chinese suppliers are the kingpins for bulk production since they’ve been producing goods worldwide. Their production capabilities have passed on through the test of times.

Along with China’s manufacturing capabilities, they have durable factory equipment, raw materials & heavy machinery. Not to mention the fact that the highly-populated country would be more than capable to fulfill the demand for production.

Higher production capability is one important factor you must consider when you are working with factories, especially when you require bulk production to fulfill the market’s demands.

Technological Capabilities

It’s an undeniable fact that China is one of the most technologically advanced countries in recent times. Production of goods on a large scale is feasible without any worries. With the country’s intense technological capabilities, Chinese factories are well-equipped with tools that increase their productivity and efficiency – while reducing overall cost of production.

As for supply chain management, the existence of China’s artificial intelligence (AI), cloud computing and other modern technologies are in place. This brought about a great innovation for the supply chain sector and positioned China as a sourcing hub for major companies across the globe.

Large Scale Production

Other countries have exported raw materials and components that massively expanded China’s supplier range. On a secondary level, this also occurs when smaller companies require components from other manufacturing units in China. Factories benefit from one another, providing each other with the materials they need that saves time and effort between both parties.

Sourcing agents in China have connections to all the suppliers and manufacturers, proving to be an advantageous position for transnational companies. When Chinese suppliers needed to import materials from other countries, they would normally require in bulk quantities – making an overall lower production cost.

Businesses that source from China, as a result, can save a lot on production cost while enjoying the convenience of offsite production. There is a way to reduce production cost further when steps are taken, such as utilizing durable & affordable packaging, including easy-to-produce product designs.

Where to Find Verified Suppliers?

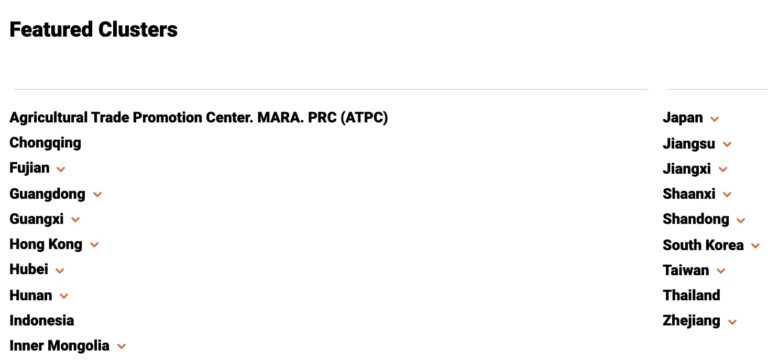

hktdc.com Sourcing has a list of verified suppliers. With a range and variety of suppliers from different parts of the world, these verified suppliers are certified through their local governments and have also achieved a certain standard of recognition as HKTDC’s certified suppliers.

The verified suppliers are often recruited through the trade promotion organisation of the local, regional & provincial government organisations, which will carry out inspections. This adds an additional assurance about the standards and quality when it comes to regulations for manufacturers in China.

It is also worth mentioning that hktdc.com Sourcing’s includes a diversified option of highly-qualified suppliers based in China, such as Foshan, Jiangmen and Zhongshan. With the advantage of accessible manufacturing in China, finding an efficient supplier would not be a challenge through the country’s large list of certified suppliers.

Verify the Credentials of the Supplier or Manufacturer

To verify the Chinese supplier or manufacturer’s credentials, the most obvious step is to rely on information available online. Sourcing Allies discusses the variety of information you need to evaluate for your next supplier. The two main criteria are:

- Whether they are indeed the factory and not a middleman.

- Whether they have the technical expertise and production capability to deliver what they promise.

There are many options you can take to verify their credentials. Other than directly asking for business licenses and other certifications.

- Ask for the factory’s audited accounts and check its Value Added Tax (VAT) invoice.

- Ask for product samples.

- Identify the factory’s Chinese name, its location and the local government office under whose jurisdiction it falls. The respective governing offices normally have factory registration records, which help verify the details they have provided to you.

Understanding the niche of certain Chinese manufacturing regions will help weed out the differences between a reseller and manufacturer. For example, die casting and plastic molding manufacturers are prevalent in Zhejiang province. If you find a supplier based in another province, that company is likely to be a reseller rather than a manufacturer, which helps you distinguish which one should be dropped from your list.

Visiting shortlisted factories on your list is also recommended. It’s been a widely suggested concept from people in the supplier/manufacturing chain. It is quite common for buyers to combine such visits along with trade fairs to get a maximum value out of their trip. Alternatively, consider a good sourcing agent to take that visit for you.

Avoid common pitfalls

Chinese suppliers are required to register under the Chinese governing authorities and obtain their unique company registration number. If a manufacturer cannot (or is unwilling) to provide you with their number, simply walk away. One way to verify their registration number is by getting in touch with their local Bureau of Industry Commerce or visit their local government website.

Another safe option is to let the potential supplier know you’ll have their factory audited before issuing any PO. Even later, you may want to inspect the production before authorising any shipments. Bringing this up as soon as possible in early conversations is important.

If they refuse or begin to make excuses, that’s a huge red flag. Factory audits are crucial to verifying supplier claims on their production capability and also help protect your investments.

Ordering reports from a third-party, especially authentication services like GloBIS, can help obtain important information on your potential supplier – ranging from legal representatives, shareholders, business scope, financial records and such.

If possible, visiting the location yourself to discuss your expectations face-to-face is another direct option.

Avoiding fraud and protecting yourself is up to your due diligence. By performing research before making any sort of transaction helps ensure your meticulousness with verification. This also ensures peace of mind when you can trust your potential supplier.

Conclusion

When it comes to doing business in China, generally speaking, it’s the ideal environment for any manufacturers across the globe. The latest numbers have shown continual growth over recent times, and the Chinese government has been regulating and implementing policies to support innovative progress in China’s manufacturing sector.

China has been proving to be a great business environment in general. A relevant HKTDC resource describes the several contributing factors which elevated China to attract more foreign investors. These factors include smooth application procedures for Foreign Investment Access, tax administration, regulated legal systems, massive domestic sales and many more.

Read more: Guide to doing business in China

As China is a massive, highly populous country, the market variety tends to be very vast. HKTDC provides frequently updated analysis on the consumer markets around China. As of recent, there is an ongoing trend in the Chinese consumer market pivoting towards health products. This includes smart living for a healthier life and an increase in expense for healthy food/supplements.

HKTDC stays up-to-date with all consumer behaviour in the Chinese market. This also includes specific behaviour for mobile users, which are broken down into many shopping behaviours. All-in-all, when considering doing business in China from their attractive perks, there is also a wide range of resources you can browse within HKTDC’s research section.

Read more: “Consumer Market in China” on HKTDC Research